|

|

|

|

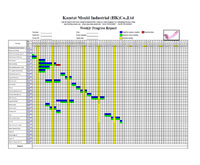

Weekly

progress report |

|

Weekly progress report and digital

mould pictures are presented to

customer once a week which show the

detailed project progress status, it

is easy for customer to control the

everything at the same time . As far

as customer concerned , we will take

great pride in the high standard of

customer service offered by KTM.

Just one phone call , or e-mail to

us and you'll see we are ready for

you at any time. Teaming up with a

Project Managers and Quality

Engineers , we ensure that projects

development goes smoothly from the

engineering side to the production . |

|

|

Material certificate and heat treatment

inspection report |

|

Material certificate and heat treatment

inspection report will absolutely guarantee

the mould material are 100% meet customer's

requirements . these related report can be

send with the mould delivery . |

|

|

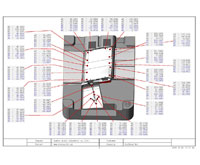

3CMM

Cavity/Core inspection report |

|

In order to further ensure the muold

dimensions and to reduce the quality

risk into a minimum .every cavity

and core must be inspected with

3CMM(3 Coordinate Measuring

Machine). this inspection report

will be submitted to you after T1. |

|

|

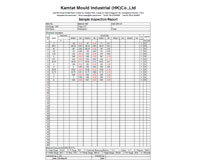

Samples inspection report

|

|

Sampling video (including mould open

and close movement, cooling

connection, a complete mould trial

process ) . Samples inspection

report will further guarantee the

good quality of the products . it

will be provided within 3 days after

samples delivery . Customer will

feel like the mould makes in their

own toolshop with such satisfactory

service because it save customer’s

much time , money and energy to fly

to China.

|

|

|

Mould vacuum package |

|

We are introducing the vacuum packing for

export mould , this new method was broken up

the traditional packing with oil stains .

the advantages of vacuum packing are : the

mold will never get rust but very clean and

can make production immediately once receive

the mould . it will save much of time and

energy or even money instead of washing .

Meanwhile , in order to better serve

customer and for future check , 2D ,3D ,

part drawings ,EDM , trial parameters and

spare parts or Hot sprue drawings if

necessary will be shipped together with the

exported mould . |

|

|

|

|